Analytical Assessments

Sims Professional Engineers offers a variety of analysis techniques aimed at ensuring your design is safe, reliable, and ready to stand the test of time. We can verify the quality of a new design before the prototype stage, or search for the cause of any problems you may have with existing equipment. Whatever your analysis needs, Sims brings the right tools for the job.

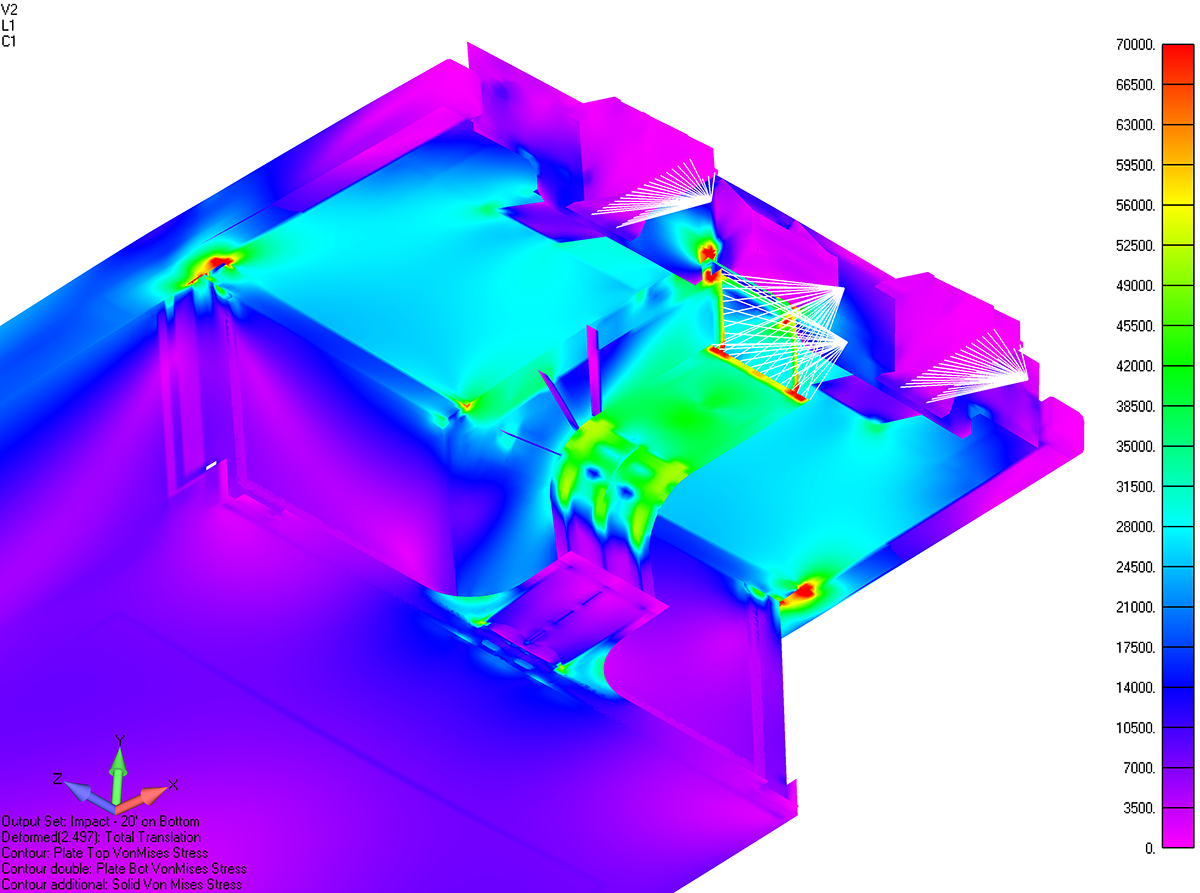

Finite Element Analysis (FEA)

Finite element analysis (FEA) is the stress and structural evaluation that determines when a structural component will deform or break from loads anticipated when placed in service. It is also a means of certifying the compliance of a structural system to a code or specification requirement. A two-or three-dimensional model of the real world parts is built with material characteristics that mathematically define the way the part will act in service.

Using a sophisticated computer model, our skilled engineers will locate the loading level at which your product will become over-stressed, causing deformation or failure. This process is ideal when applied before the product is manufactured. However, it is equally effective when applied to parts or components that have failed in service. This forensic work helps to pinpoint the cause of field problems, as well as develop practical solutions to these problems. Finite element analysis is also used to optimize a design for weight and size to ensure that a sound product is constructed. Value engineering functions benefit greatly from the power of the finite element technique.

Finite Element Analysis Services:

- Two- and three-dimensional solid modeling

- Linear, non-linear

- Static and dynamic loading

- Elastic and plastic analysis

- Large structural analysis for transportation vehicles

- Part analysis -- small cast, machined, or fabricated parts

- Buckling Analysis

- Modal Analysis

Classical Analysis

While FEA is the modern analysis tool, many applications – especially of new designs – are well suited for a “quick look” using well-established classical analysis techniques. Sims is particularly adept at such work, and as such offers a full range of analytical tools.

Dynamic Analysis NUCARS®

At Sims PE we use state-of-the-art analysis techniques, including NUCARS® (New and Untried Cars Analytical Regime System), for determining vehicle performance through mathematical simulations. Other dynamic analysis programs are used to analyze for pitch and bounce, twist and roll, and high speed stability. Other aspects of dynamic performance, including modal analysis are analyzed using the finite element analysis program Femap. These techniques help identify unwanted natural frequency problems and other dynamic responses of the structures and suspensions. The same techniques are used to analyze ride quality, wheel/rail contact forces, and other safety and performance characteristics.